The Wassara way of installing dam instrumentation casing

The WICS water-powered technology from Wassara is the fastest and most cost-effective method to drill casing for monitoring instruments in dams.

faster installation

water consumption

There are always safety concerns when drilling in dam structures. With Wassaras water-powered drilling technology, these concerns are minimal. The unique technology, which has been used in numerous dam rehabilitation projects over the years, greatly reduces the pressure applied to the rock formation.

Furthermore, by combining Wassaras DTH technology with a filter tube, installing instruments can be carried out much faster than with traditional methods. A traditional installation of a 2” tube usually takes up to two full working days.

A Wassara installation of a 2” tube takes approximately two hours. This is up to eight times faster than comparable technologies.

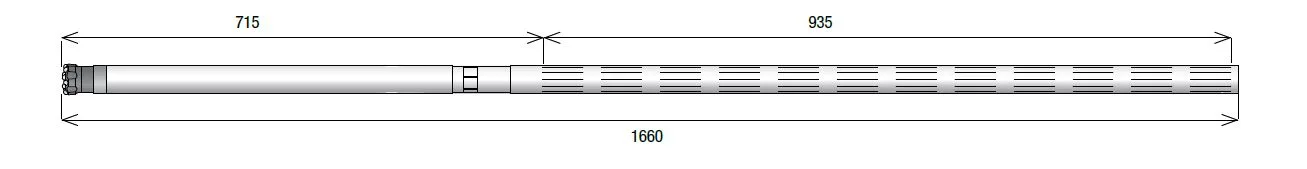

The Wassara dam instrumentation casing system comprise of:

| Hole size Ø | 43 mm |

| Filter tube material | Stainless steel |

| Outer filter diameter Ø | 38 mm |

| Inner filter diameter Ø | 26 mm |

| Slot witdh | 0.5 mm |

| Casing tube material | Galvanized steel |

| Casing tube outer diameter Ø | 40 mm |

| Casing tube inner diameter Ø | 30 mm |

| Casing tube length | 1 or 2 m |

By eliminating the temporary installation of a 4” casing, the time spent on installation is greatly reduced. This also gives less impact on the dam structure.

| Steps | The Wassara Way | The traditional method |

| 1 | Drill down to target depth. The inner flow tube prevents the water from escaping through the filter. | Install a 4” casing by drilling it down to target depth. |

| 2 | When the target depth is reached, the inner flow tube is retrieved by an extractor tool. | The 2” instrument tube is installed inside the 4” tube. |

| 3 | The remaining area is filled with filtration sand. | |

| 4 | The 4” tube is extracted. |

See our Dam-related Casestudies below.