Tunneling

New York City needs a new water supply system, and the contractor for this big project decided to use the Wassara W50 hammer on their Robbin’s TBM-machine

New York City, USA

Kiewit - Shea Constructors

W50 Hammer

New York City needs a new water supply system. The contractor for this big project decided to use Wassara’s W50 hammer on their Robbin’s TBM-machine, to get long and straight holes, constant drill rate and a technique that didn’t get effected by high water pressure in the formation.

All needed to enable high quality exploration drilling while constructing the new Delaware Aqueduct.

Background

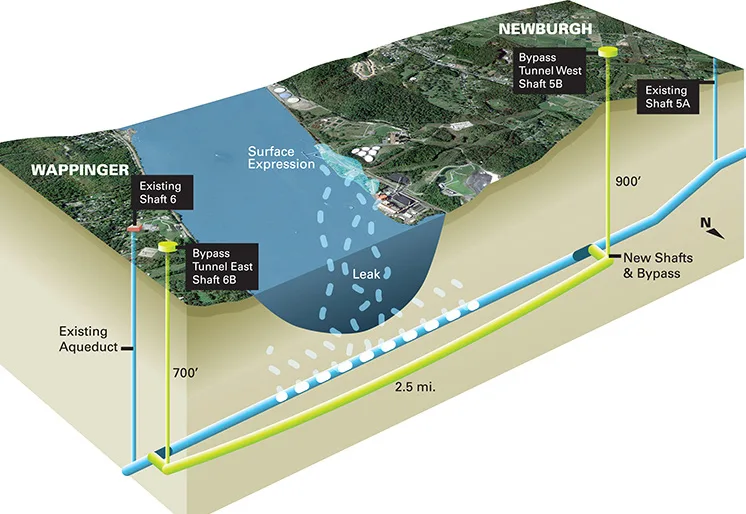

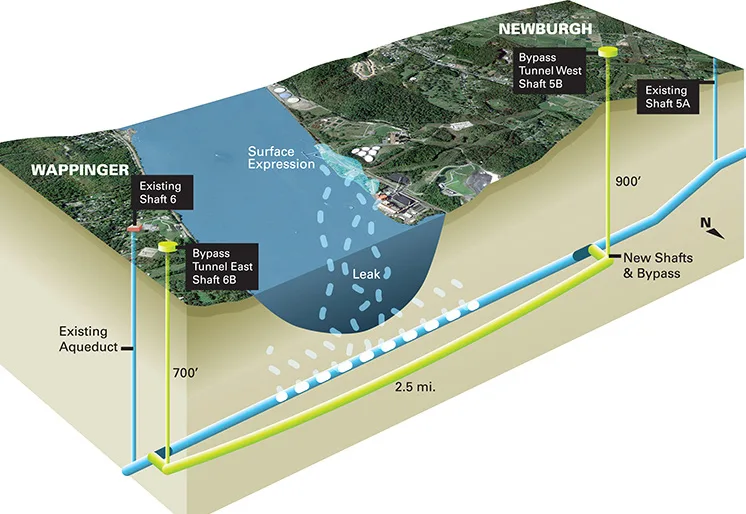

The Delaware Aqueduct is an aqueduct in the New York City water supply system. It takes water from the Rondout reservoir on the west bank of the Hudson River through the Chelsea Pump Station, then into the West Branch, ending in at Hillview in Yonkers, New York. The aqueduct was constructed between 1939 and 1945 and carries approximately half of New York City’s water supply of 4 900 000 m3 per day.

Over the years, the water system has suffered increasing damages resulting in leakages. The largest of the leakage occurs in a part of the tunnel just when it goes under the Hudson River.

The NYCDEP (New York City Department of Environmental Protection) is therefore building a 4.0 km bypass tunnel beneath the Hudson, which will allow it to bypass the leak. Construction began in November 2013 and was expected to be finished in 2021.

Benefits by using the Wassara technology

Traditionally, exploration drilling is performed with top hammer equipment, but in this case the contractor has chosen to drill with Wassara’s water-powered technology instead. One of the reasons is that the contractor wants to drill longer exploration holes, up to 100 meters, thereby reducing the number of production stops because of probe drilling.

Moreover, Wassara’s technology has a relatively constant rate of penetration, regardless of how long the borehole is, while top hammers drop in drill rate the deeper you go.

Another advantage of Wassara’s water-powered technology is the hole straightness. It increases the likelihood that the exploration hole is within the intended tunnel profile.

In addition, water pressure may occur locally in the formation of up to 27 bar, which can cause major problems for the entire project, but for Wassara’s hammer, which normally works with pressure up to 200 bar, 27 bar is a relatively low pressure.

| DTH Hammer | W50 Hammer |

| Drill rods | Ø 63,5 mm |

| Rig | Ripamonti |

| Water pump | WASP 80 |

| Borehole length | Up to 120 m |

| Scope of drilling | 18 500 m |

| Geologic formation | Limestone, shale and hard rock (up to 370 MPa) |

| Project time | January 2018 – August 2019 |

See our featured Case studies below to learn what real world Tunneling-projects our technology as been a part of.